- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

pup joint drilling

The Importance of PUP Joint Drilling in the Oil and Gas Industry

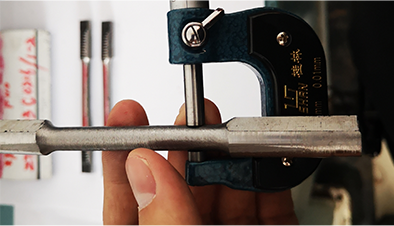

In the oil and gas industry, the efficiency and reliability of drilling operations are critical for maximizing production and minimizing costs. One technique that has gained significant attention in recent years is the use of PUP joints (Premium Upset Pipe) in drilling operations. PUP joints serve as an effective solution to enhance drilling safety, improve performance, and elongate the lifespan of drilling equipment.

The Importance of PUP Joint Drilling in the Oil and Gas Industry

Moreover, PUP joints are manufactured with premium materials and sophisticated upset designs that enhance their strength and durability. This feature is particularly vital when drilling in challenging environments, such as deepwater locations or areas with high-pressure formations. The enhanced mechanical properties of PUP joints allow them to withstand the extreme conditions often encountered during drilling, thus minimizing the likelihood of incidents that could lead to costly downtime.

pup joint drilling

Another crucial aspect of PUP joint drilling is its contribution to the overall drilling efficiency. Given the complexity of oil and gas extraction, every second of reduced drilling time translates into significant cost savings. PUP joints enable smoother transitions between different sections of the drill string, thereby decreasing resistance and improving the rate of penetration (ROP). This faster drilling speed not only enhances productivity but also allows operators to access reservoir formations more quickly, facilitating efficient resource recovery.

PUP joint drilling also promotes operational flexibility. As the drilling environment or geological conditions change, the ability to quickly adjust the drill string configuration can lead to better outcomes. PUP joints can be easily incorporated into different drill string designs, making it easier for operators to adapt to varying conditions without the need for extensive reconfiguration. This adaptability is essential for maintaining operational momentum and meeting tight timelines.

Moreover, the implementation of PUP joints aligns with the industry's increasing focus on sustainability. By extending the life of drilling equipment and reducing the frequency of replacements, operators can minimize waste and lower their environmental impact. Additionally, enhancing drilling efficiency aids in reducing the overall carbon footprint of drilling activities, which is increasingly becoming a priority within the sector.

In conclusion, PUP joint drilling represents a significant advancement within the oil and gas industry, offering numerous benefits that enhance operational safety, efficiency, and sustainability. As drilling technology continues to evolve, the integration of PUP joints will undoubtedly play a pivotal role in shaping the future of drilling operations, paving the way for more effective resource extraction and a more sustainable industry. As operators seek to optimize their drilling practices, the importance of PUP joints can no longer be overlooked.

-

Well Casing Extension Couplings – Applications and InstallationNewsJun.06,2025

-

Types of Crossover Subs in Drilling & CompletionNewsJun.06,2025

-

Key Features of High-Quality Tubing Pup JointsNewsJun.06,2025

-

Installation and Maintenance Tips for Steel Couplings for PipeNewsJun.06,2025

-

How to Select the Right Pup Joint for Oil & Gas OperationsNewsJun.06,2025

-

Applications of Stainless Steel Pipe CouplingsNewsJun.06,2025