- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Jan . 30, 2025 05:33

Back to list

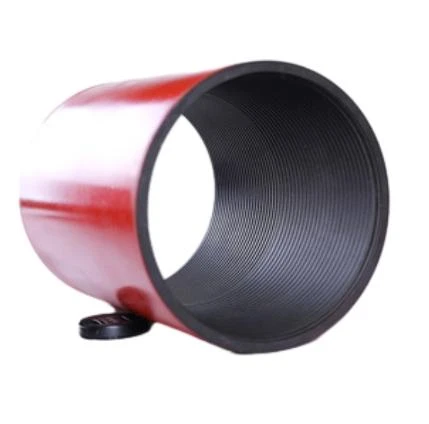

Tubing Pup Joint

In the realm of oil and gas industry equipment, pup joint manufacturers have steadily emerged as indispensable contributors to the seamless operation of well drilling processes. Their expertise in producing high-quality short tubular components known as pup joints plays a pivotal role in the continuity and efficiency of drilling activities.

Authoritativeness in the field involves a recognition by industry peers as being a leader in pup joint manufacturing. Esteemed manufacturers often participate in or contribute to industry standards and specifications, such as those set by the American Petroleum Institute (API). By adhering to these standards, they demonstrate their commitment to maintaining the highest quality and safety benchmarks. Furthermore, they actively engage in continuous improvement practices, often driven by customer feedback and evolving industry needs, positioning themselves as forward-thinking entities ready to tackle future challenges. Trustworthiness, a critical factor in choosing a pup joint manufacturer, is established through a track record of reliable service and customer satisfaction. Reputed manufacturers typically have a portfolio of successfully completed projects and long-standing relationships with top-tier oil and gas companies around the world. Their credibility is often reinforced by testimonials and case studies that highlight their ability to deliver solutions on time and within budget. In a market where efficiency and reliability can dictate the pace of operations, selecting pup joint manufacturers who epitomize experience, expertise, authoritativeness, and trustworthiness becomes paramount. Their crucial role in supplying quality pup joints ensures not only the operational success of drilling activities but also reinforces the safety and structural integrity of the entire well infrastructure. This commitment to excellence makes them invaluable partners in the ever-evolving landscape of oil and gas exploration.

Authoritativeness in the field involves a recognition by industry peers as being a leader in pup joint manufacturing. Esteemed manufacturers often participate in or contribute to industry standards and specifications, such as those set by the American Petroleum Institute (API). By adhering to these standards, they demonstrate their commitment to maintaining the highest quality and safety benchmarks. Furthermore, they actively engage in continuous improvement practices, often driven by customer feedback and evolving industry needs, positioning themselves as forward-thinking entities ready to tackle future challenges. Trustworthiness, a critical factor in choosing a pup joint manufacturer, is established through a track record of reliable service and customer satisfaction. Reputed manufacturers typically have a portfolio of successfully completed projects and long-standing relationships with top-tier oil and gas companies around the world. Their credibility is often reinforced by testimonials and case studies that highlight their ability to deliver solutions on time and within budget. In a market where efficiency and reliability can dictate the pace of operations, selecting pup joint manufacturers who epitomize experience, expertise, authoritativeness, and trustworthiness becomes paramount. Their crucial role in supplying quality pup joints ensures not only the operational success of drilling activities but also reinforces the safety and structural integrity of the entire well infrastructure. This commitment to excellence makes them invaluable partners in the ever-evolving landscape of oil and gas exploration.

Next:

Latest news

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025

Related Products