- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Jul . 04, 2024 01:50

Back to list

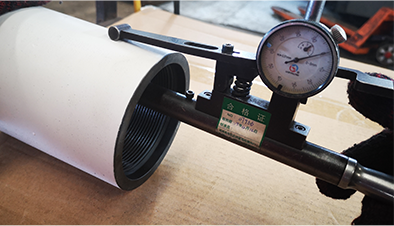

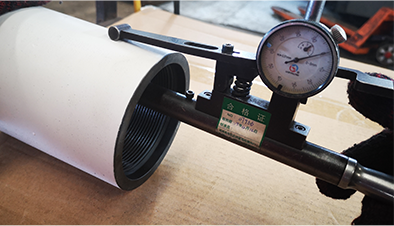

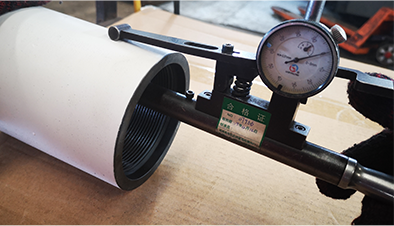

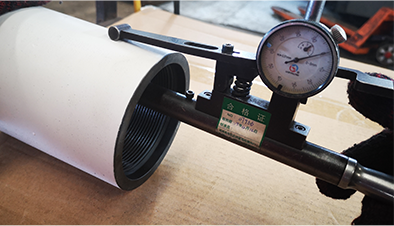

Similarity between well casing coupling and other components used in oil well construction.

Well casing coupling, also known as a casing joint, is an essential component in oil and gas well construction. It is used to connect two pieces of well casing together, providing a sealed and secure connection that prevents leaks and ensures the integrity of the wellbore.

One of the key functions of a well casing coupling is to provide structural support to the well casing. By connecting two sections of casing together, the coupling helps to maintain the overall strength and stability of the well. This is especially important in deep or challenging drilling environments, where the casing may be exposed to high pressures or extreme temperatures.

In addition to providing structural support, well casing couplings also play a crucial role in preventing leaks and maintaining well integrity. The connection between two sections of casing must be secure and sealed to prevent any fluids or gases from escaping into the surrounding environment. This helps to protect the wellbore from contamination and ensures the safety of both the workers on site and the surrounding environment.

There are several different types of well casing couplings available, each designed for specific applications and operating conditions

There are several different types of well casing couplings available, each designed for specific applications and operating conditions There are several different types of well casing couplings available, each designed for specific applications and operating conditions

There are several different types of well casing couplings available, each designed for specific applications and operating conditions

There are several different types of well casing couplings available, each designed for specific applications and operating conditions

There are several different types of well casing couplings available, each designed for specific applications and operating conditions well casing coupling. For example, threaded couplings are commonly used in shallow wells or for temporary casing, while welded couplings are preferred for deeper wells or when extra strength is required.

Proper installation and maintenance of well casing couplings are essential to ensure their effective performance. During installation, it is important to carefully inspect the coupling for any defects or damage that could compromise its integrity. Additionally, regular inspections and maintenance checks should be conducted to identify any potential issues and prevent problems before they escalate.

Overall, well casing couplings play a critical role in the construction and operation of oil and gas wells. They provide structural support, prevent leaks, and help to maintain the integrity of the wellbore. By using high-quality couplings and following proper installation and maintenance procedures, operators can ensure the safety and efficiency of their well construction projects.

well casing coupling. For example, threaded couplings are commonly used in shallow wells or for temporary casing, while welded couplings are preferred for deeper wells or when extra strength is required.

Proper installation and maintenance of well casing couplings are essential to ensure their effective performance. During installation, it is important to carefully inspect the coupling for any defects or damage that could compromise its integrity. Additionally, regular inspections and maintenance checks should be conducted to identify any potential issues and prevent problems before they escalate.

Overall, well casing couplings play a critical role in the construction and operation of oil and gas wells. They provide structural support, prevent leaks, and help to maintain the integrity of the wellbore. By using high-quality couplings and following proper installation and maintenance procedures, operators can ensure the safety and efficiency of their well construction projects.

There are several different types of well casing couplings available, each designed for specific applications and operating conditions

There are several different types of well casing couplings available, each designed for specific applications and operating conditions

There are several different types of well casing couplings available, each designed for specific applications and operating conditions

There are several different types of well casing couplings available, each designed for specific applications and operating conditions well casing coupling. For example, threaded couplings are commonly used in shallow wells or for temporary casing, while welded couplings are preferred for deeper wells or when extra strength is required.

Proper installation and maintenance of well casing couplings are essential to ensure their effective performance. During installation, it is important to carefully inspect the coupling for any defects or damage that could compromise its integrity. Additionally, regular inspections and maintenance checks should be conducted to identify any potential issues and prevent problems before they escalate.

Overall, well casing couplings play a critical role in the construction and operation of oil and gas wells. They provide structural support, prevent leaks, and help to maintain the integrity of the wellbore. By using high-quality couplings and following proper installation and maintenance procedures, operators can ensure the safety and efficiency of their well construction projects.

well casing coupling. For example, threaded couplings are commonly used in shallow wells or for temporary casing, while welded couplings are preferred for deeper wells or when extra strength is required.

Proper installation and maintenance of well casing couplings are essential to ensure their effective performance. During installation, it is important to carefully inspect the coupling for any defects or damage that could compromise its integrity. Additionally, regular inspections and maintenance checks should be conducted to identify any potential issues and prevent problems before they escalate.

Overall, well casing couplings play a critical role in the construction and operation of oil and gas wells. They provide structural support, prevent leaks, and help to maintain the integrity of the wellbore. By using high-quality couplings and following proper installation and maintenance procedures, operators can ensure the safety and efficiency of their well construction projects. Latest news

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025

Related Products