- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

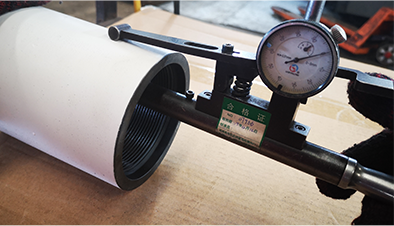

special clearance coupling

Understanding Special Clearance Couplings A Comprehensive Overview

In the world of mechanical engineering, the importance of precision and reliability cannot be overstated. One of the key components that facilitate this in various machinery and systems is the coupling. Among the different types of couplings, special clearance couplings hold significant value due to their unique design and functional advantages.

A coupling, in general, is a device used to connect two shafts mechanically at their ends for the purpose of transmitting power. However, special clearance couplings are distinct in that they allow for a degree of movement or flexibility between the connected shafts. This flexibility is primarily due to their design, which incorporates a certain amount of clearance that accommodates misalignment and thermal expansion.

The special clearance coupling is particularly beneficial in applications where precise alignment between shafts is difficult to maintain. In most machinery, shafts may not always be perfectly aligned due to manufacturing tolerances, installation variances, or thermal effects during operation. When shafts are misaligned, excess stress can be placed on the machinery, leading to premature wear or catastrophic failure. This is where special clearance couplings excel, as they can compensate for these misalignments without transmitting harmful forces to the connected components.

These couplings are commonly used in industries such as automotive, aerospace, and manufacturing. For instance, in automotive applications, they are often used to connect various drivetrain components that experience fluctuating loads and vibrations. The inherent flexibility within the special clearance coupling helps to absorb shocks and vibrations, leading to smoother operation and enhanced durability.

special clearance coupling

Moreover, the design of special clearance couplings often incorporates robust materials and advanced engineering techniques to optimize performance. The materials used tend to be resistant to wear and corrosion, which enhances the lifespan of the coupling. Many manufacturers also offer customizable options for these couplings, allowing engineers to select specific dimensions, clearances, and material specifications tailored to particular applications.

However, choosing the right type of coupling requires careful consideration. Factors such as load requirements, speed of operation, and environmental conditions must all be taken into account. Engineers must also consider the installation requirements and maintenance protocols as part of the overall system design.

In addition to their practical advantages, special clearance couplings also contribute to the overall efficiency of mechanical systems. By reducing the likelihood of failure and the associated downtime, these couplings can enhance productivity and reduce overall maintenance costs.

In conclusion, special clearance couplings play a pivotal role in modern mechanical engineering. Their ability to accommodate shaft misalignment and reduce transmission stress makes them invaluable in a variety of applications. As technology advances, the design and materials of these couplings will likely continue to evolve, further enhancing their capabilities and applications across multiple industries. Understanding and utilizing special clearance couplings can lead to more efficient and reliable machinery, showcasing the integral role they play in mechanical systems worldwide.

-

Well Casing Extension Couplings – Applications and InstallationNewsJun.06,2025

-

Types of Crossover Subs in Drilling & CompletionNewsJun.06,2025

-

Key Features of High-Quality Tubing Pup JointsNewsJun.06,2025

-

Installation and Maintenance Tips for Steel Couplings for PipeNewsJun.06,2025

-

How to Select the Right Pup Joint for Oil & Gas OperationsNewsJun.06,2025

-

Applications of Stainless Steel Pipe CouplingsNewsJun.06,2025