Jun . 13, 2024 12:19

Back to list

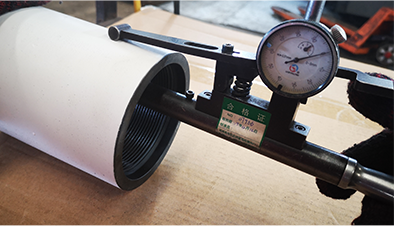

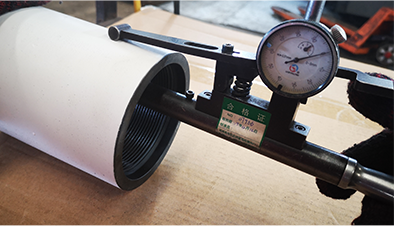

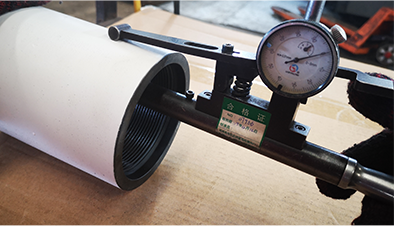

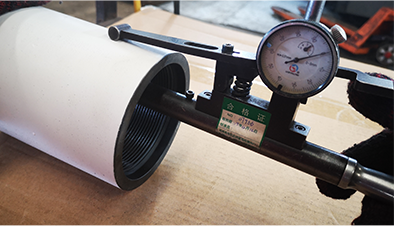

Stainless steel connector for durable pipe linkage.

The Indispensable Role of Stainless Steel Couplings in Modern Engineering

Stainless steel couplings, an integral part of various engineering and industrial applications, have carved a niche for themselves due to their exceptional durability and corrosion resistance. These connectors, often referred to by the URL-friendly term stainless steel coupling, are a testament to the power of engineering innovation and the potential of stainless steel as a material.

A coupling is a device used to connect two shafts together, transmitting power from one to another. In the context of stainless steel, these couplings offer a superior blend of strength, flexibility, and resilience. The 'stainless' in stainless steel refers to its ability to resist staining or corroding under most conditions, making it ideal for use in harsh environments or where exposure to water, chemicals, or extreme temperatures is prevalent.

The primary advantage of stainless steel couplings lies in their corrosion resistance. Thanks to the presence of chromium, which forms an invisible oxide layer on the surface, they can withstand rust and corrosion caused by moisture or chemicals. This feature makes them particularly suitable for applications in the oil and gas industry, chemical processing plants, marine environments, and food and beverage processing.

Moreover, stainless steel couplings exhibit high tensile strength and fatigue resistance, allowing them to handle heavy loads and endure repetitive stress without failure. They also have excellent thermal and electrical conductivity, making them apt for applications that require heat dissipation or electrical connections.

The versatility of stainless steel couplings is another key factor contributing to their widespread use

The versatility of stainless steel couplings is another key factor contributing to their widespread use The versatility of stainless steel couplings is another key factor contributing to their widespread use

The versatility of stainless steel couplings is another key factor contributing to their widespread use

The versatility of stainless steel couplings is another key factor contributing to their widespread use

The versatility of stainless steel couplings is another key factor contributing to their widespread use stainless steel coupling. They come in various types, including flexible, rigid, and sleeve couplings, each designed to cater to specific requirements. Flexible couplings, for instance, can accommodate misalignment, while rigid couplings provide a direct transfer of torque with no allowance for movement.

In addition, the aesthetic appeal of stainless steel, with its lustrous finish, makes it a preferred choice for applications where appearance matters, such as in architectural and automotive designs.

Despite the initial higher cost compared to other materials, the long-term benefits of stainless steel couplings, such as low maintenance costs and extended service life, make them a cost-effective solution. They are also recyclable, aligning with the growing trend of sustainability in modern engineering.

In conclusion, the role of stainless steel couplings in modern engineering is profound and far-reaching. From facilitating efficient power transmission in industrial machinery to ensuring safety in critical infrastructure, they embody the robustness and reliability that define modern engineering solutions. As technology advances and industries evolve, the importance of stainless steel couplings is likely to continue growing, further solidifying their position as a cornerstone of engineering innovation.

stainless steel coupling. They come in various types, including flexible, rigid, and sleeve couplings, each designed to cater to specific requirements. Flexible couplings, for instance, can accommodate misalignment, while rigid couplings provide a direct transfer of torque with no allowance for movement.

In addition, the aesthetic appeal of stainless steel, with its lustrous finish, makes it a preferred choice for applications where appearance matters, such as in architectural and automotive designs.

Despite the initial higher cost compared to other materials, the long-term benefits of stainless steel couplings, such as low maintenance costs and extended service life, make them a cost-effective solution. They are also recyclable, aligning with the growing trend of sustainability in modern engineering.

In conclusion, the role of stainless steel couplings in modern engineering is profound and far-reaching. From facilitating efficient power transmission in industrial machinery to ensuring safety in critical infrastructure, they embody the robustness and reliability that define modern engineering solutions. As technology advances and industries evolve, the importance of stainless steel couplings is likely to continue growing, further solidifying their position as a cornerstone of engineering innovation.

The versatility of stainless steel couplings is another key factor contributing to their widespread use

The versatility of stainless steel couplings is another key factor contributing to their widespread use

The versatility of stainless steel couplings is another key factor contributing to their widespread use

The versatility of stainless steel couplings is another key factor contributing to their widespread use stainless steel coupling. They come in various types, including flexible, rigid, and sleeve couplings, each designed to cater to specific requirements. Flexible couplings, for instance, can accommodate misalignment, while rigid couplings provide a direct transfer of torque with no allowance for movement.

In addition, the aesthetic appeal of stainless steel, with its lustrous finish, makes it a preferred choice for applications where appearance matters, such as in architectural and automotive designs.

Despite the initial higher cost compared to other materials, the long-term benefits of stainless steel couplings, such as low maintenance costs and extended service life, make them a cost-effective solution. They are also recyclable, aligning with the growing trend of sustainability in modern engineering.

In conclusion, the role of stainless steel couplings in modern engineering is profound and far-reaching. From facilitating efficient power transmission in industrial machinery to ensuring safety in critical infrastructure, they embody the robustness and reliability that define modern engineering solutions. As technology advances and industries evolve, the importance of stainless steel couplings is likely to continue growing, further solidifying their position as a cornerstone of engineering innovation.

stainless steel coupling. They come in various types, including flexible, rigid, and sleeve couplings, each designed to cater to specific requirements. Flexible couplings, for instance, can accommodate misalignment, while rigid couplings provide a direct transfer of torque with no allowance for movement.

In addition, the aesthetic appeal of stainless steel, with its lustrous finish, makes it a preferred choice for applications where appearance matters, such as in architectural and automotive designs.

Despite the initial higher cost compared to other materials, the long-term benefits of stainless steel couplings, such as low maintenance costs and extended service life, make them a cost-effective solution. They are also recyclable, aligning with the growing trend of sustainability in modern engineering.

In conclusion, the role of stainless steel couplings in modern engineering is profound and far-reaching. From facilitating efficient power transmission in industrial machinery to ensuring safety in critical infrastructure, they embody the robustness and reliability that define modern engineering solutions. As technology advances and industries evolve, the importance of stainless steel couplings is likely to continue growing, further solidifying their position as a cornerstone of engineering innovation. Latest news

-

Tubing Crossover - API Compatible, Custom Sizes, In StockNewsNov.10,2025

-

Tubing Coupling | High-Strength, Leak-Proof Steel CouplingsNewsNov.10,2025

-

Wholesale API Threading Casing Coupling | API 5CT, Fast ShipNewsNov.10,2025

-

Pup Joint Supplier | API Certified, Custom, Quick ShipNewsNov.10,2025

-

Pup Joint Manufacturers | Precision Machined, Fast DeliveryNewsNov.10,2025

-

Tubing Coupling | Precision Steel, Leak-Proof, Fast DeliveryNewsNov.03,2025

Related Products