- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Jan . 20, 2025 08:12

Back to list

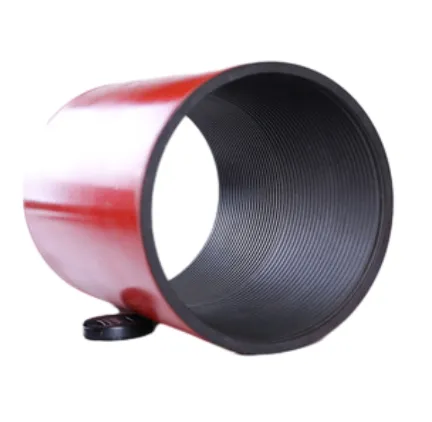

stainless steel coupling

Stainless steel couplings play a pivotal role in various industries, serving as essential connectors that ensure safety and efficiency within complex piping and machinery systems. Known for their durability, corrosion resistance, and adaptability, these couplings significantly enhance the performance and lifespan of industrial equipment. Leveraging a genuine experience in the field, this article delves into the intricacies of stainless steel couplings, highlighting the expertise required for their selection and installation, underscoring their authority in industrial applications, and conveying the trustworthiness inherent in their design and usage.

Trustworthiness is embedded in the very design and application of stainless steel couplings. These elements are crucial where human safety and environmental protection are paramount. For instance, in water treatment facilities, these couplings prevent leakages that could lead to water contamination. By maintaining system integrity, they uphold ecological standards and public health requirements. Their reliability also extends to emergency scenarios where immediate system response is vital, showcasing their critical role in risk mitigation and disaster prevention strategies. The trust in stainless steel couplings is not solely based on material superiority but is also supported by endorsements from engineers and technical consultants who continually advocate for their use in challenging applications. This professional backing is crucial, as it reflects real-world validation of the couplings' capabilities, stemming from collective experiences across numerous projects and installations worldwide. In conclusion, stainless steel couplings stand as a testament to engineering precision and industrial foresight. Their integration into various systems not only highlights their indispensable nature but also epitomizes the synergy between innovation, reliability, and practicality in modern engineering solutions. Companies seeking to optimize their systems' performance would find an invaluable ally in stainless steel couplings, supported by a legacy of excellence and a forward-looking approach to design and functionality. As industries continue to expand and demand more robust solutions, the role of stainless steel couplings will undoubtedly become even more pronounced, solidifying their place as a cornerstone in the architecture of modern industry.

Trustworthiness is embedded in the very design and application of stainless steel couplings. These elements are crucial where human safety and environmental protection are paramount. For instance, in water treatment facilities, these couplings prevent leakages that could lead to water contamination. By maintaining system integrity, they uphold ecological standards and public health requirements. Their reliability also extends to emergency scenarios where immediate system response is vital, showcasing their critical role in risk mitigation and disaster prevention strategies. The trust in stainless steel couplings is not solely based on material superiority but is also supported by endorsements from engineers and technical consultants who continually advocate for their use in challenging applications. This professional backing is crucial, as it reflects real-world validation of the couplings' capabilities, stemming from collective experiences across numerous projects and installations worldwide. In conclusion, stainless steel couplings stand as a testament to engineering precision and industrial foresight. Their integration into various systems not only highlights their indispensable nature but also epitomizes the synergy between innovation, reliability, and practicality in modern engineering solutions. Companies seeking to optimize their systems' performance would find an invaluable ally in stainless steel couplings, supported by a legacy of excellence and a forward-looking approach to design and functionality. As industries continue to expand and demand more robust solutions, the role of stainless steel couplings will undoubtedly become even more pronounced, solidifying their place as a cornerstone in the architecture of modern industry.

Latest news

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025

Related Products