Feb . 17, 2025 12:44

Back to list

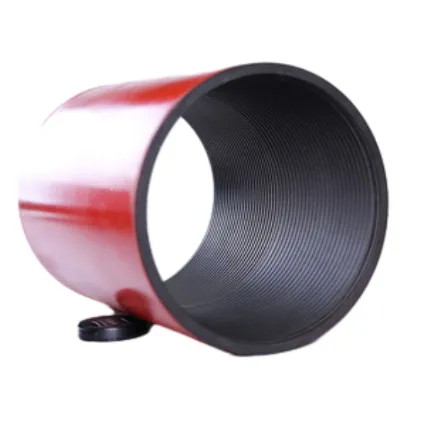

stainless steel pipe coupling

Stainless steel pipe couplings are indispensable components in plumbing and industrial applications, acting as vital connectors that ensure the stability and continuity of piping systems. The growing demand for durable and reliable pipe solutions has thrust stainless steel couplings into the spotlight. Thanks to their unique combination of durability, versatility, and resistance to corrosion, they are preferred in various industries, from construction to manufacturing.

The trustworthiness of stainless steel pipe couplings can be illustrated through their widespread adoption in critical applications. Industries such as oil and gas, where safety is non-negotiable, extensively use these couplings due to their proven performance under pressure. Additionally, their application in food processing environments is a testament to their ability to withstand hygienic standards, where non-reactivity with food substances is crucial. Businesses and individuals considering stainless steel pipe couplings should prioritize sourcing from reputable manufacturers. A trusted supplier not only provides a product that meets quality standards but also offers technical support, ensuring that the coupling is the best fit for the intended application. This decision significantly impacts the longevity and reliability of the piping system, reinforcing the importance of trust in supplier relationships. The practical experiences of engineers and technicians further enhance the reliability of these couplings. Real-world applications have demonstrated their resilience under various conditions, such as extreme temperatures and pressures, and their ability to maintain integrity over extended periods with minimal maintenance. These experiential insights are invaluable, offering assurance to prospective users about the long-term benefits and cost-effectiveness of choosing stainless steel pipe couplings. In conclusion, the expertise, authoritativeness, and trustworthiness associated with stainless steel pipe couplings make them a pivotal choice for numerous industries. Their robust construction, backed by stringent standards, and their proven track record in demanding applications, establish them as a reliable component in any pipeline system. Whether dealing with the rigors of industrial environments or meeting hygiene standards in food processing, these couplings deliver a performance that stands the test of time. For those looking to invest in quality and dependability, stainless steel pipe couplings represent a sound choice that aligns with both current and future requirements.

The trustworthiness of stainless steel pipe couplings can be illustrated through their widespread adoption in critical applications. Industries such as oil and gas, where safety is non-negotiable, extensively use these couplings due to their proven performance under pressure. Additionally, their application in food processing environments is a testament to their ability to withstand hygienic standards, where non-reactivity with food substances is crucial. Businesses and individuals considering stainless steel pipe couplings should prioritize sourcing from reputable manufacturers. A trusted supplier not only provides a product that meets quality standards but also offers technical support, ensuring that the coupling is the best fit for the intended application. This decision significantly impacts the longevity and reliability of the piping system, reinforcing the importance of trust in supplier relationships. The practical experiences of engineers and technicians further enhance the reliability of these couplings. Real-world applications have demonstrated their resilience under various conditions, such as extreme temperatures and pressures, and their ability to maintain integrity over extended periods with minimal maintenance. These experiential insights are invaluable, offering assurance to prospective users about the long-term benefits and cost-effectiveness of choosing stainless steel pipe couplings. In conclusion, the expertise, authoritativeness, and trustworthiness associated with stainless steel pipe couplings make them a pivotal choice for numerous industries. Their robust construction, backed by stringent standards, and their proven track record in demanding applications, establish them as a reliable component in any pipeline system. Whether dealing with the rigors of industrial environments or meeting hygiene standards in food processing, these couplings deliver a performance that stands the test of time. For those looking to invest in quality and dependability, stainless steel pipe couplings represent a sound choice that aligns with both current and future requirements.

Latest news

-

Tubing Crossover - API Compatible, Custom Sizes, In StockNewsNov.10,2025

-

Tubing Coupling | High-Strength, Leak-Proof Steel CouplingsNewsNov.10,2025

-

Wholesale API Threading Casing Coupling | API 5CT, Fast ShipNewsNov.10,2025

-

Pup Joint Supplier | API Certified, Custom, Quick ShipNewsNov.10,2025

-

Pup Joint Manufacturers | Precision Machined, Fast DeliveryNewsNov.10,2025

-

Tubing Coupling | Precision Steel, Leak-Proof, Fast DeliveryNewsNov.03,2025

Related Products