- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

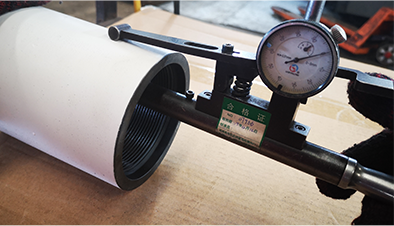

steel coupling

The Versatile Applications of Steel Couplings in Modern Engineering

Steel couplings are essential components in various engineering applications, serving as a bridge between two shafts, ensuring efficient power transmission and alignment while accommodating various operational challenges. As industries increasingly demand durable, reliable solutions for connecting rotating components, steel couplings have emerged as a preferred choice due to their strength, versatility, and performance under stress.

Understanding Steel Couplings

At its core, a coupling is a device that connects two shafts, enabling the transfer of torque while allowing for some level of misalignment. Steel couplings are particularly favored in industrial settings because of their exceptional tensile strength and resistance to wear and tear. They are fabricated from high-quality steel, which provides durability and longevity, making them suitable for diverse applications ranging from automotive to aerospace, and manufacturing to heavy machinery.

Types of Steel Couplings

There are various types of steel couplings, each designed for specific applications and requirements. Some common types include

1. Rigid Couplings These couplings are designed to provide a firm connection between shafts, ensuring no relative movement occurs. They are ideal for high-precision applications where alignment is critical.

2. Flexible Couplings In contrast to rigid couplings, flexible couplings can accommodate some degree of misalignment and vibrations, making them suitable for applications where slight errors in alignment may occur.

3. Oldham Couplings Featuring three parts — two hubs and a center disc — Oldham couplings are particularly useful for applications requiring the compensation of parallel misalignments.

4. Grid Couplings These consist of a grid-type insert that helps absorb shock loads and vibrations. This design allows for some flexibility while providing robust torque transmission.

5. Sleeve Couplings Often used in low-torque applications, sleeve couplings connect two shafts using a cylindrical sleeve, ideal for short shaft systems with minimal misalignment.

Applications in Various Industries

steel coupling

1. Automotive In the automotive industry, steel couplings play a pivotal role in connecting the engine to the transmission and other drivetrain components. Given the high-stress environment, robust steel couplings are employed to withstand torque fluctuations and vibrations.

2. Manufacturing Manufacturing setups often utilize steel couplings in conveyor systems, motors, and rotary tables. Their ability to minimize downtime through reliable connections allows for continuous operations in production lines.

3. Aerospace The aerospace sector demands precision and reliability. Steel couplings are used in various applications, from engines to control systems, where performance and safety are paramount.

4. Oil and Gas In the oil and gas industry, equipment is subjected to extreme conditions, including high torque and harsh environmental factors. Steel couplings are chosen for their resilience, ensuring safe and efficient operation of drilling rigs and pumping systems.

Advantages of Steel Couplings

The use of steel couplings brings numerous benefits to engineers and manufacturers alike

- Strength and Durability Steel couplings can withstand high loads, making them suitable for heavy-duty applications where performance is critical.

- Resistance to Wear and Tear Their robust material properties make steel couplings resistant to abrasion, ensuring a longer service life.

- Versatility With various designs available, steel couplings can be tailored to fit different operational needs, accommodating various levels of misalignment and torsional vibrations.

- Cost-Effectiveness While the initial investment may be higher than other materials, the long-term durability and reduced maintenance costs make steel couplings a cost-efficient solution.

Conclusion

Steel couplings are indispensable in modern engineering, offering a reliable solution for connecting shafts across a wide range of applications. Their strength, versatility, and ability to perform under stress make them a crucial component in ensuring operational efficiency and longevity in various industries. As technological advancements continue to drive the demand for high-performance machinery, the role of steel couplings will undoubtedly remain significant, paving the way for innovation and improved engineering solutions. By understanding and leveraging the capabilities of steel couplings, engineers can design systems that not only meet but exceed the demands of today’s fast-paced industrial environment.

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025