- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Jan . 14, 2025 10:17

Back to list

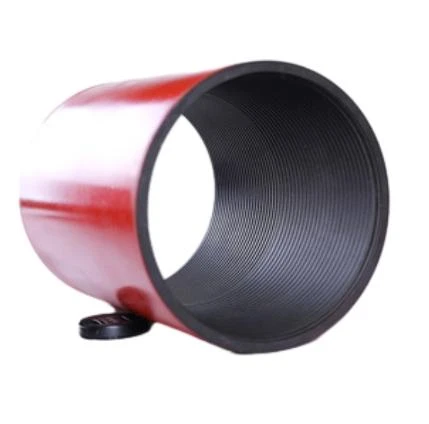

steel couplings for pipe

The world of oil and gas exploration relies heavily on the efficiency and safety of drilling operations. A critical component in this intricate mechanism is the API tubing coupling, an essential part that ensures the secure transportation of fluids from the reservoir to the surface. Leveraging years of experience and expertise in the industry, it is imperative to understand the nuances of these couplings, their design, and their overall impact on drilling operations.

While technological advancements continue to evolve the design and functionality of these couplings, they also highlight an industry-wide trust in established standards. API's specifications provide a benchmark for quality and performance that professionals consistently rely upon. This trustworthiness is a cornerstone of the industry, ensuring that operations proceed with minimal risk and maximal integrity. Additionally, real-world experiences from the field emphasize the importance of regular maintenance and inspection. Operator testimonials often point to the longevity and efficiency of API tubing couplings in operational settings when properly cared for. This experience-backed knowledge fosters a trustworthy relationship between manufacturers and operators, promoting a culture of safety and responsiveness. Unlike simple market transactions, purchasing API tubing couplings is a strategic decision. It demands an authoritative understanding of material science, engineering principles, and industry standards. The decision-making process involves experts who can assess compatibility with existing systems while anticipating future challenges, thereby reflecting an authoritative approach. In conclusion, an in-depth focus on API tubing couplings reveals them to be more than just a product - they are a testament to the oil and gas industry’s commitment to safety, efficiency, and innovation. The experience derived from their deployment, the expertise in their engineering, the authority established through compliance with industry standards, and the trust built through consistent reliability makes them invaluable in the field. Understanding these facets is vital for any organization aiming to thrive in the competitive and challenging landscape of oil and gas exploration. Ensuring the correct selection and application of these components not only improves operational efficiency but also enhances overall safety procedures, marking a significant influence on the success of drilling endeavors.

While technological advancements continue to evolve the design and functionality of these couplings, they also highlight an industry-wide trust in established standards. API's specifications provide a benchmark for quality and performance that professionals consistently rely upon. This trustworthiness is a cornerstone of the industry, ensuring that operations proceed with minimal risk and maximal integrity. Additionally, real-world experiences from the field emphasize the importance of regular maintenance and inspection. Operator testimonials often point to the longevity and efficiency of API tubing couplings in operational settings when properly cared for. This experience-backed knowledge fosters a trustworthy relationship between manufacturers and operators, promoting a culture of safety and responsiveness. Unlike simple market transactions, purchasing API tubing couplings is a strategic decision. It demands an authoritative understanding of material science, engineering principles, and industry standards. The decision-making process involves experts who can assess compatibility with existing systems while anticipating future challenges, thereby reflecting an authoritative approach. In conclusion, an in-depth focus on API tubing couplings reveals them to be more than just a product - they are a testament to the oil and gas industry’s commitment to safety, efficiency, and innovation. The experience derived from their deployment, the expertise in their engineering, the authority established through compliance with industry standards, and the trust built through consistent reliability makes them invaluable in the field. Understanding these facets is vital for any organization aiming to thrive in the competitive and challenging landscape of oil and gas exploration. Ensuring the correct selection and application of these components not only improves operational efficiency but also enhances overall safety procedures, marking a significant influence on the success of drilling endeavors.

Next:

Latest news

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025

Related Products