- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Efficient Techniques for Managing Tubing and Casing in Oil and Gas Operations

Tubing and Casing Essential Components in Oil and Gas Production

In the oil and gas industry, the extraction of hydrocarbons from deep within the Earth is a complex and multifaceted process. Among the critical elements that support this endeavor are tubing and casing, integral components that ensure the integrity, efficiency, and safety of drilling operations. This article explores the roles, types, and significance of tubing and casing in hydrocarbon production.

Understanding Casing

Casing refers to the series of steel pipes that are installed in the borehole after drilling to stabilize the wellbore and isolate the different geological formations encountered during the drilling process. The primary function of casing is to prevent the collapse of the wellbore, and to protect the groundwater supply from contamination by hydrocarbons and other fluids. Casing is typically run in stages, with each section being cemented in place to create a solid barrier.

There are various types of casing, including surface casing, intermediate casing, and production casing. Surface casing is the first string set in the well and is designed to protect shallow aquifers and ensure that drilling operations can proceed safely. Intermediate casing is used to withstand higher pressures and can be run to different depths depending on the geological conditions and the design of the well. Production casing is the final casing string that allows for the extraction of oil or gas from the reservoir and runs the full length of the wellbore.

The Role of Tubing

While casing serves to protect the well and separate formations, tubing serves a different yet equally critical purpose. Tubing refers to the smaller-diameter pipes inserted inside the casing that provide a conduit for the flow of oil, gas, or water from the reservoir to the surface. Tubing must be durable enough to withstand the high pressures and corrosive substances encountered during production.

Tubing installations can vary in diameter and thickness based on the specific requirements of the well and the production methods employed. The choice of tubing material is also essential; common materials include carbon steel and stainless steel, both of which offer resistance to corrosion and mechanical failure.

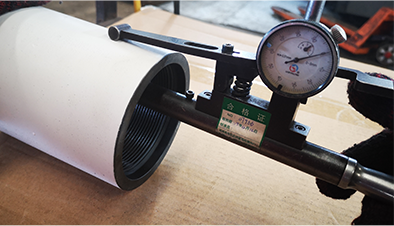

tubing and casing

Importance of Tubing and Casing

Together, tubing and casing play a vital role in the efficiency and safety of oil and gas extraction

. The integrity of the wellbore is critical for maintaining pressure during extraction, preventing blowouts, and ensuring that hydrocarbons can flow freely to the surface. Proper installation and maintenance of casing and tubing systems help mitigate risks associated with well integrity, reducing the potential for leaks or spills that can harm the environment.Moreover, effective casing and tubing design can enhance production rates and facilitate the implementation of advanced recovery techniques. For example, in hydraulic fracturing operations, the design of the tubing can help optimize the injection and flow of fracturing fluids, thereby increasing the yield of oil and gas from the reservoir.

Challenges and Innovations

Despite their essential roles, tubing and casing systems are not without challenges. Corrosion, mechanical wear, and pressures encountered at great depths can compromise the integrity of both tubing and casing, leading to failures that require costly repairs and can halt production. To address these challenges, ongoing advancements in materials science and engineering practices continue to improve the design and durability of these components.

Innovations such as the use of corrosion-resistant alloys, advanced sealing technologies, and smart monitoring systems are being developed to enhance the reliability of tubing and casing installations. Additionally, advancements in computer modeling and simulation allow for better prediction of well behavior under different conditions, aiding in the design of more effective survival strategies.

Conclusion

In conclusion, tubing and casing are fundamental to the success of hydrocarbon production in the oil and gas industry. By providing structural integrity, facilitating the flow of products, and ensuring environmental protection, these components are critical throughout the lifecycle of a well. As technology continues to evolve, the industry can expect to see innovations that further enhance the performance and safety of tubing and casing systems, securing a sustainable future for energy extraction.

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025