- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Jan . 14, 2025 10:26

Back to list

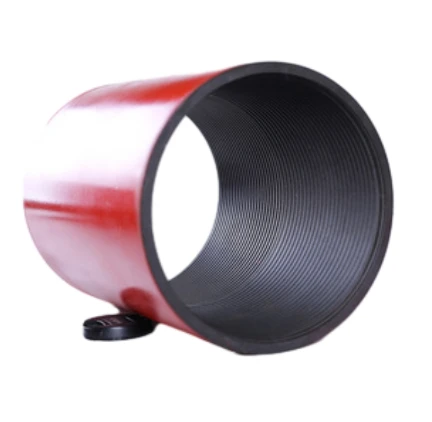

Tubing Coupling

Aluminum pipe couplings and fittings serve as indispensable components in a wide array of industrial applications. As an alloy known for its lightweight properties, corrosion resistance, and versatility, aluminum has become a cornerstone material in constructing robust and efficient piping systems. Whether optimizing an HVAC system, constructing a complex plumbing network, or designing aerospace components, understanding the unique advantages of aluminum fittings is crucial.

Given the professional nature of utilizing aluminum fittings, it's essential to address common concerns related to their application. While aluminum is generally resistant to corrosion, it can react with certain chemicals under specific conditions. Therefore, an authoritative approach to installation would include a thorough analysis of the environmental conditions to ensure compatibility and performance integrity. Trustworthiness in marketing these products comes from transparent communication about their capabilities and limitations. By providing comprehensive guidance and support, suppliers and manufacturers can build trust with customers and reaffirm their position as industry leaders. For businesses looking to leverage these fittings in their operations, partnering with credible suppliers who offer robust guarantees and support is paramount. Access to technical documentation, peer-reviewed studies, and certifications provides the assurance needed to make informed decisions. In conclusion, aluminum pipe couplings and fittings offer unparalleled advantages in strength, weight, and sustainability. With a blend of professional expertise and real-world application experience, choosing these components enhances system efficiency and longevity. By aligning with reputable suppliers and maintaining transparent, informed practices, industries can confidently utilize these fittings to achieve superior performance and reliability.

Given the professional nature of utilizing aluminum fittings, it's essential to address common concerns related to their application. While aluminum is generally resistant to corrosion, it can react with certain chemicals under specific conditions. Therefore, an authoritative approach to installation would include a thorough analysis of the environmental conditions to ensure compatibility and performance integrity. Trustworthiness in marketing these products comes from transparent communication about their capabilities and limitations. By providing comprehensive guidance and support, suppliers and manufacturers can build trust with customers and reaffirm their position as industry leaders. For businesses looking to leverage these fittings in their operations, partnering with credible suppliers who offer robust guarantees and support is paramount. Access to technical documentation, peer-reviewed studies, and certifications provides the assurance needed to make informed decisions. In conclusion, aluminum pipe couplings and fittings offer unparalleled advantages in strength, weight, and sustainability. With a blend of professional expertise and real-world application experience, choosing these components enhances system efficiency and longevity. By aligning with reputable suppliers and maintaining transparent, informed practices, industries can confidently utilize these fittings to achieve superior performance and reliability.

Next:

Latest news

-

Well Casing Extension Couplings – Applications and InstallationNewsJun.06,2025

-

Types of Crossover Subs in Drilling & CompletionNewsJun.06,2025

-

Key Features of High-Quality Tubing Pup JointsNewsJun.06,2025

-

Installation and Maintenance Tips for Steel Couplings for PipeNewsJun.06,2025

-

How to Select the Right Pup Joint for Oil & Gas OperationsNewsJun.06,2025

-

Applications of Stainless Steel Pipe CouplingsNewsJun.06,2025

Related Products