- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Understanding Tubing Crossovers in Oil and Gas Industry Applications and Techniques

Understanding Tubing Crossover A Key Concept in Oil and Gas Operations

In the vast and complex world of oil and gas extraction, the term tubing crossover frequently arises. This concept is crucial for operators, engineers, and those involved in well management and design. Tubing crossover refers to a specific application in the context of well production, particularly in the arrangement and functioning of the production tubing within a wellbore.

What is Tubing Crossover?

At its core, tubing crossover refers to the point at which the production tubing from different wells intersect or connect in a manner that allows them to work in unison. This could involve various configurations where multiple production tubes come together to optimize oil and gas extraction from a single reservoir or to manage production from multiple zones in a well efficiently. The tubing crossover setup is particularly common in fields where multiple wells are drilled in close proximity, leading to an intricate network of tubular components.

Importance of Tubing Crossover

1. Efficiency in Production One of the primary advantages of utilizing tubing crossover systems is the enhancement of production efficiency. By enabling the flow of hydrocarbons from multiple zones or wells through a single line, operators can minimize surface equipment and streamline the transportation of hydrocarbons to the surface.

2. Cost Reduction Establishing a tubing crossover can significantly reduce costs associated with drilling and completing multiple wells as it allows operators to maximize output from existing wells. Fewer surface facilities and equipment lead to decreased capital and operational expenditures.

3. Enhanced Recovery Tubing crossovers can optimize the recovery processes by enabling the use of advanced techniques such as gas lift, water flooding, or other enhanced oil recovery (EOR) methods efficiently across multiple zones. This integration allows for better pressure maintenance and more effective extraction from different formations.

4. Simplified Operations From an operational standpoint, a tubing crossover simplifies the management of multiple wells. Instead of handling individual production lines, operators can monitor and control a single system, thereby reducing the potential for operational errors and improving overall management of resources.

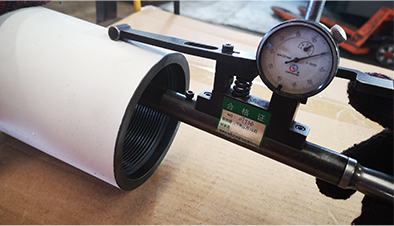

tubing crossover

Challenges in Implementing Tubing Crossover

Despite the advantages, implementing tubing crossover systems does come with its challenges.

1. Complex Design and Engineering The design of a crossover system must be meticulously planned, taking into account the different well pressures, fluid characteristics, and mechanical properties. Engineers must ensure that the structural integrity is maintained, preventing failures that could result in costly leaks or shutdowns.

2. Maintenance Issues With multiple wells feeding into a single crossover system, maintenance can become complicated. Identifying and rectifying issues can be more challenging than in conventional systems where troubles are isolated to individual wells.

3. Operational Risks Integrating production from multiple wells raises the stakes when it comes to risk management. A problem in one well could potentially affect the production of others, requiring robust monitoring systems and contingency plans.

Future of Tubing Crossover

As technology advances, the future of tubing crossover systems looks promising. Digital solutions such as real-time monitoring and advanced analytics can help operators manage these systems more effectively, predicting maintenance needs and optimizing production rates. Innovations in materials science may also lead to more resilient tubing designs that can withstand the rigors of complex operational environments.

In summary, tubing crossover is a crucial aspect of modern oil and gas production practices. By understanding its advantages and challenges, operators can effectively leverage this concept to enhance efficiency, reduce costs, and optimize resource recovery. As the industry continues to evolve, the importance of effective design and implementation of tubing crossover systems will only grow, paving the way for more sustainable and productive oil and gas operations.

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025