- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Exploring the Range of Tubing Solutions for Industrial Applications

Exploring the World of Tubing Products Versatility, Applications, and Innovations

Tubing products play a crucial role in various industries, providing essential solutions for transportation, protection, and process management. From medical applications to automotive uses, tubing products come in a multitude of materials, sizes, and designs, each tailored to meet the specific demands of different sectors. In this article, we will delve into the various types of tubing products, their applications, and the innovative trends shaping their future.

Types of Tubing Products

Tubing can be classified based on its material composition, which significantly impacts its usability and performance. Common materials include

1. Plastic Tubing Often made from polyethylene, polypropylene, and PVC, plastic tubing is lightweight, flexible, and resistant to corrosion. Its applications range from fluid transfer in medical devices to household plumbing.

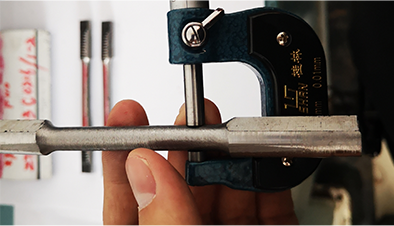

2. Metal Tubing Stainless steel and aluminum are prevalent in metal tubing. These materials provide strength and durability, making them ideal for high-pressure applications such as gas and hydraulic systems in the automotive and aerospace industries.

3. Rubber Tubing Known for its flexibility and resilience, rubber tubing finds extensive use in pneumatic systems and automotive applications. Silicone rubber tubing is particularly popular in medical devices due to its biocompatibility.

4. Composite Tubing Combining materials like carbon fiber and plastics, composite tubing products offer high strength-to-weight ratios. They are increasingly used in aerospace, automotive, and sporting goods.

Applications of Tubing Products

The versatility of tubing products allows them to be employed in an array of applications across multiple industries

- Medical Industry In the healthcare sector, tubing products are vital for delivering medications, fluids, and nutrients. They are also integral to various medical devices, such as IV systems and catheters. Medical tubing must adhere to strict regulations concerning biocompatibility, ensuring patient safety.

tubing products

- Automotive and Aerospace Tubing products in these industries provide essential functionalities, including fluid transfer, exhaust systems, and wiring protection. Innovations such as lightweight composite tubing enhance performance while contributing to fuel efficiency.

- Industrial Applications In manufacturing and chemical processing, tubing products convey gases and liquids under varying pressures and temperatures. Selecting the appropriate material is crucial to ensure operational efficiency and safety.

- Consumer Products Everyday items, from hoses for garden watering to flexible straws, utilize various tubing products. Consumer demand for durability and sustainability drives innovations in this space, with many manufacturers exploring biodegradable materials.

Innovations in Tubing Products

Recent technological advancements are shaping the future of tubing products. Innovations include

1. Smart Tubing The integration of sensors within tubing products allows real-time monitoring of fluid flow, pressure, and temperature. This technology is especially valuable in the medical field for monitoring patients more effectively or in industrial applications to optimize processes.

2. Eco-Friendly Materials As environmental concerns rise, manufacturers are exploring sustainable materials for tubing. Biodegradable and recyclable options are becoming more common, addressing the need for environmental stewardship in production.

3. Custom Fabrication Advances in manufacturing technology, such as 3D printing, are enabling custom designs for tubing products. This trend allows for tailored solutions that meet specific customer needs, optimizing performance across various applications.

4. Enhanced Durability Recent developments in material science have resulted in tubing that can withstand extreme conditions, such as high temperatures and corrosive environments. These innovations expand the range of applications for tubing products and improve their longevity.

Conclusion

As we navigate an increasingly interconnected and technologically advanced world, tubing products will continue to play a pivotal role across multiple industries. Their versatility, coupled with innovations in materials and design, positions them as fundamental components in addressing contemporary challenges. Whether facilitating medical treatments, enhancing automotive efficiency, or providing solutions for industrial processes, the evolution of tubing products reflects a commitment to progress and adaptability in an ever-changing marketplace. As manufacturers embrace new technologies and sustainable practices, the future of tubing products looks promising, with endless possibilities on the horizon.

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025