- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Feb . 10, 2025 11:28

Back to list

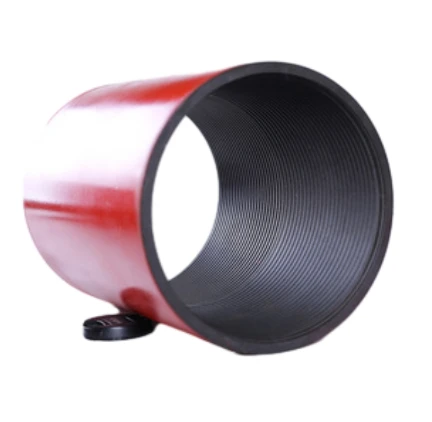

tubing pup joint

In the world of oil and gas exploration, the tubing pup joint plays an indispensable role. These short lengths of pipe are essential in the wellbore, allowing adjustments in the string length to ensure optimal performance and safety. The significance of tubing pup joints cannot be overstated; they are pivotal in achieving precise tubing depths and ensuring that the infrastructure can withstand the pressures of subsurface environments.

Authoritativeness in the realm of tubing pup joints is backed by industry regulations and recognized certifications. Companies producing these components often hold ISO certifications, which attest to the quality and reliability of their products. Design engineers consulting on pup joint utilization offer trusted advice, highlighting the need for compliance with American Petroleum Institute (API) standards. These standards are a benchmark for ensuring safety and efficacy in oil and gas operations—a testament to the trustworthiness that needs to be inherent in every piece of equipment used downhole. Trustworthiness is also built through careful monitoring and documentation of tubing pup joint performance in situ. Field data collected during operations provide valuable insights into the longevity and reliability of these components under various conditions. Trusted companies provide comprehensive tracking systems and data analysis tools, assisting operators in understanding wear patterns and proactively maintaining their infrastructures. Hence, continuous feedback and analysis underscore trust in the evolving specifications of these critical tools. This information not only ensures better immediate site safety and efficiency but also contributes to the iterative design improvements on future products. In summary, the tubing pup joint, though a seemingly minor component in the broader scope of oil and gas operations, embodies experience, expertise, authoritativeness, and trustworthiness. It's through a deep understanding of their function, precise engineering practices, adherence to established industry standards, and ongoing performance analysis that these components prove their worth. As the industry continues to evolve, the careful selection and utilization of tubing pup joints remain a testament to the skill and innovation that drive successful petroleum extraction.

Authoritativeness in the realm of tubing pup joints is backed by industry regulations and recognized certifications. Companies producing these components often hold ISO certifications, which attest to the quality and reliability of their products. Design engineers consulting on pup joint utilization offer trusted advice, highlighting the need for compliance with American Petroleum Institute (API) standards. These standards are a benchmark for ensuring safety and efficacy in oil and gas operations—a testament to the trustworthiness that needs to be inherent in every piece of equipment used downhole. Trustworthiness is also built through careful monitoring and documentation of tubing pup joint performance in situ. Field data collected during operations provide valuable insights into the longevity and reliability of these components under various conditions. Trusted companies provide comprehensive tracking systems and data analysis tools, assisting operators in understanding wear patterns and proactively maintaining their infrastructures. Hence, continuous feedback and analysis underscore trust in the evolving specifications of these critical tools. This information not only ensures better immediate site safety and efficiency but also contributes to the iterative design improvements on future products. In summary, the tubing pup joint, though a seemingly minor component in the broader scope of oil and gas operations, embodies experience, expertise, authoritativeness, and trustworthiness. It's through a deep understanding of their function, precise engineering practices, adherence to established industry standards, and ongoing performance analysis that these components prove their worth. As the industry continues to evolve, the careful selection and utilization of tubing pup joints remain a testament to the skill and innovation that drive successful petroleum extraction.

Next:

Latest news

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025

Related Products