- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Feb . 08, 2025 06:26

Back to list

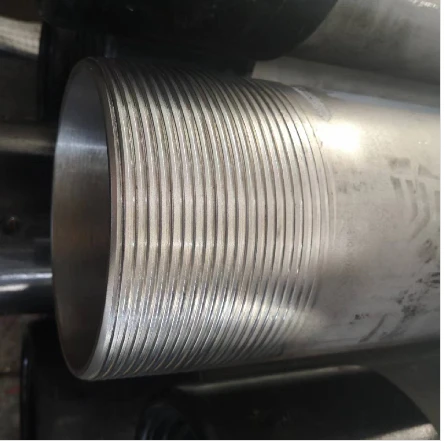

Caing Coupling

Well tubing and casing are critical components in the oil and gas industry, serving as the backbone for efficient and safe extraction processes. These intricately designed tubular structures not only prevent the collapse of wells but also isolate various pressure zones, ensuring the well operates optimally throughout its lifecycle.

Authoritativeness and trust are built through long-term field observations. An overlooked aspect of well tubing and casing is their interaction with one another. Tubing that’s not adequately sized or mismatched with the casing can lead to reduced flow efficiency or mechanical failures. Drawing from expert recommendations, a harmonious sizing strategy where the tubing allows for optimal flow rates without compromising structural integrity is paramount. Continuous monitoring and analytical software now allow for predictive maintenance, identifying weaknesses in tubing and casing before they become catastrophic, thus safeguarding investments. Adopting new technologies is bolstered by a deep-seated understanding of the well environment. For fields facing high-temperature and high-pressure (HTHP) conditions, specialty casing and tubing designs can offer formidable benefits. Industry-backed research indicates that premium casing connections can withstand significant axial loads and extreme thermal cycles. Thus, working with a team that not only possesses technical prowess but also adheres to stringent safety protocols can lead to superior operational outcomes. The regulatory landscape surrounding well construction is evolving, with increased attention on tubing and casing specifications. Industry authorities continue to publish standards that ensure operational safety and environmental compliance. Staying updated with these standards is not just about compliance, but about integrating best practices that align with industry advancements. Trustworthy industry partners often participate in these regulatory discussions, providing you with the foresight and materials necessary to exceed standard requirements. In conclusion, the mastery of well tubing and casing extends beyond mere selection—it demands a cultivation of knowledge across product capabilities and environmental applications. By leveraging industry expertise, innovative technologies, and trusted field experiences, your operations can achieve not only enhanced safety and efficiency but also sustainability in extraction processes. The integration of experience-based insights and authoritative guidance lays the foundation for superior decision-making in the oil and gas sector.

Authoritativeness and trust are built through long-term field observations. An overlooked aspect of well tubing and casing is their interaction with one another. Tubing that’s not adequately sized or mismatched with the casing can lead to reduced flow efficiency or mechanical failures. Drawing from expert recommendations, a harmonious sizing strategy where the tubing allows for optimal flow rates without compromising structural integrity is paramount. Continuous monitoring and analytical software now allow for predictive maintenance, identifying weaknesses in tubing and casing before they become catastrophic, thus safeguarding investments. Adopting new technologies is bolstered by a deep-seated understanding of the well environment. For fields facing high-temperature and high-pressure (HTHP) conditions, specialty casing and tubing designs can offer formidable benefits. Industry-backed research indicates that premium casing connections can withstand significant axial loads and extreme thermal cycles. Thus, working with a team that not only possesses technical prowess but also adheres to stringent safety protocols can lead to superior operational outcomes. The regulatory landscape surrounding well construction is evolving, with increased attention on tubing and casing specifications. Industry authorities continue to publish standards that ensure operational safety and environmental compliance. Staying updated with these standards is not just about compliance, but about integrating best practices that align with industry advancements. Trustworthy industry partners often participate in these regulatory discussions, providing you with the foresight and materials necessary to exceed standard requirements. In conclusion, the mastery of well tubing and casing extends beyond mere selection—it demands a cultivation of knowledge across product capabilities and environmental applications. By leveraging industry expertise, innovative technologies, and trusted field experiences, your operations can achieve not only enhanced safety and efficiency but also sustainability in extraction processes. The integration of experience-based insights and authoritative guidance lays the foundation for superior decision-making in the oil and gas sector.

Next:

Latest news

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025

Related Products