- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Understanding the distinctions between casing and tubing in oil and gas operations

Differences Between Casing and Tubing in Oil and Gas Production

In the oil and gas industry, the terms casing and tubing refer to two essential components of a well, each serving a distinct purpose. Understanding the differences between the two is crucial for anyone involved in drilling, production, or well maintenance. This article aims to clarify these differences, highlighting their roles, characteristics, and applications.

Casing The Structural Backbone

Casing refers to the series of steel pipes that are installed in a drilled well to provide structural integrity and prevent the surrounding geological formations from collapsing into the borehole. Casing is typically set in various sections, known as strings, which are cemented in place to secure them and create a barrier against fluids. This prevents the migration of ground water and protects the well from contamination.

There are several types of casing, including surface casing, intermediate casing, and production casing, each serving a specific purpose

1. Surface Casing This is the first casing installed, covering the uppermost section of the well. It protects freshwater aquifers and is typically installed at a shallow depth. 2. Intermediate Casing Installed after the surface casing, this type is used when drilling through unstable formations. It provides additional stability and helps control wellbore pressure.

3. Production Casing The last casing string installed, it allows for the extraction of hydrocarbons. It is placed in the section of the well that produces oil or gas.

Casing also plays a critical role in managing well pressures and preventing blowouts. By containing these pressures, casing ensures a safe drilling operation.

Tubing The Means of Production

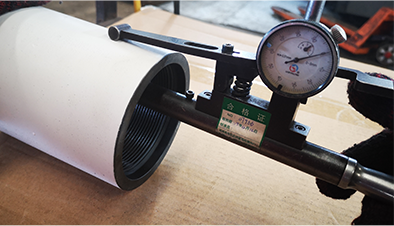

On the other hand, tubing is the smaller diameter pipe installed within the casing. Its primary purpose is to transport hydrocarbons from the production zone to the surface. Tubing is designed to handle the pressures and temperatures encountered in production environments and is usually made of high-strength steel or other corrosion-resistant materials.

The installation of tubing occurs after the casing has been set and cemented. It is a crucial component for enabling the flow of oil or gas, and it is typically fitted with various accessories, such as packers and safety valves, to enhance functionality. The main types of tubing used include

what are the differences between casing and tubing?

1. Production Tubing Specifically designed for the transport of hydrocarbons. It comes in different sizes depending on the production requirements.

2. Injection Tubing Used for injecting fluids, such as water or gas, into the well for enhanced oil recovery or pressure maintenance.

3. Flowline Tubing Transfers produced fluids from the wellhead to processing facilities.

Key Differences

The differences between casing and tubing can be summarized as follows

1. Functionality Casing provides structural support and prevents contamination of groundwater, while tubing serves as the conduit for transporting oil and gas to the surface.

2. Placement Casing is installed first during the drilling process, while tubing is placed inside the casing after the completion of the well.

3. Material and Diameter Casing is typically larger and thicker to withstand external pressures, while tubing is smaller and designed to endure internal pressures during production.

4. Maintenance Casing requires a more permanent installation as it is cemented in place, whereas tubing can be relatively easier to replace or repair as needed.

In summary, casing and tubing are both vital to the successful operation of oil and gas wells, yet they serve distinct roles within the well structure. Casing provides necessary support and safety, while tubing facilitates the actual flow of hydrocarbons from the reservoir. Understanding these differences is crucial for effective drilling and production operations, ultimately contributing to the efficiency and safety of resource extraction.

-

Tubing Pup Joints: Essential Components for Oil and Gas OperationsNewsJul.10,2025

-

Pup Joints: Essential Components for Reliable Drilling OperationsNewsJul.10,2025

-

Pipe Couplings: Connecting Your World EfficientlyNewsJul.10,2025

-

Mastering Oilfield Operations with Quality Tubing and CasingNewsJul.10,2025

-

High-Quality Casing Couplings for Every NeedNewsJul.10,2025

-

Boost Your Drilling Efficiency with Premium Crossover Tools & Seating NipplesNewsJul.10,2025