Feb . 18, 2025 07:17

Back to list

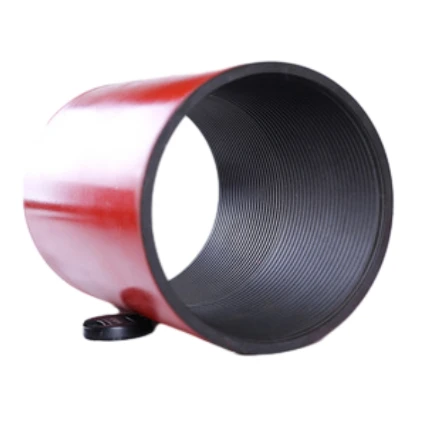

wholesale l80 casing coupling

In the dynamic world of oil and gas exploration, the selection of appropriate casing couplings plays a crucial role in ensuring operational efficiency and safety. Among the most sought-after products in this category is the L80 casing coupling, renowned for its robust performance and reliability. This article delves into the nuanced aspects of L80 casing couplings, providing an in-depth understanding catered to both industry veterans and newcomers alike.

The authority of L80 casing coupling as a preferred choice is bolstered by its widespread acceptance in the industry. Major oil field operators often list these couplings in their approved material specifications, underscoring their trust in the product’s performance. Testimonials from field engineers frequently highlight the ease of installation and maintenance as significant advantages of L80 couplings. Moreover, the product's resilience under fluctuating pressures is frequently noted in case studies that accentuate its application in drilling and production operations globally. Trustworthiness in L80 casing couplings is not merely a claim; it is validated through rigorous testing and quality assurance processes. Manufacturers adhere to stringent quality control measures, including non-destructive testing methods such as ultrasonic testing and magnetic particle inspection, to detect any flaws that could compromise performance. The result is a high-caliber product that meets the exacting standards of industry regulatory bodies and customers’ specific requirements. Lastly, navigating the realm of wholesale purchasing for L80 casing couplings requires strategic insight. Potential buyers should prioritize suppliers with established reputations for reliability and technical support. An experienced supplier will offer not just competitive pricing but also comprehensive after-sales services, including advice on installation and maintenance best practices. This added layer of support can be invaluable, particularly for companies operating within tight margins or those new to the complexities of casing installation. In conclusion, the wholesale purchase of L80 casing couplings should be informed by an understanding of material properties, compatibility, and the quality assurance processes. By focusing on these elements, companies can enhance their operational safety and efficiency, ensuring seamless operations across their drilling endeavors.

The authority of L80 casing coupling as a preferred choice is bolstered by its widespread acceptance in the industry. Major oil field operators often list these couplings in their approved material specifications, underscoring their trust in the product’s performance. Testimonials from field engineers frequently highlight the ease of installation and maintenance as significant advantages of L80 couplings. Moreover, the product's resilience under fluctuating pressures is frequently noted in case studies that accentuate its application in drilling and production operations globally. Trustworthiness in L80 casing couplings is not merely a claim; it is validated through rigorous testing and quality assurance processes. Manufacturers adhere to stringent quality control measures, including non-destructive testing methods such as ultrasonic testing and magnetic particle inspection, to detect any flaws that could compromise performance. The result is a high-caliber product that meets the exacting standards of industry regulatory bodies and customers’ specific requirements. Lastly, navigating the realm of wholesale purchasing for L80 casing couplings requires strategic insight. Potential buyers should prioritize suppliers with established reputations for reliability and technical support. An experienced supplier will offer not just competitive pricing but also comprehensive after-sales services, including advice on installation and maintenance best practices. This added layer of support can be invaluable, particularly for companies operating within tight margins or those new to the complexities of casing installation. In conclusion, the wholesale purchase of L80 casing couplings should be informed by an understanding of material properties, compatibility, and the quality assurance processes. By focusing on these elements, companies can enhance their operational safety and efficiency, ensuring seamless operations across their drilling endeavors.

Latest news

-

Tubing Crossover - API Compatible, Custom Sizes, In StockNewsNov.10,2025

-

Tubing Coupling | High-Strength, Leak-Proof Steel CouplingsNewsNov.10,2025

-

Wholesale API Threading Casing Coupling | API 5CT, Fast ShipNewsNov.10,2025

-

Pup Joint Supplier | API Certified, Custom, Quick ShipNewsNov.10,2025

-

Pup Joint Manufacturers | Precision Machined, Fast DeliveryNewsNov.10,2025

-

Tubing Coupling | Precision Steel, Leak-Proof, Fast DeliveryNewsNov.03,2025

Related Products