Mar . 04, 2025 02:21

Back to list

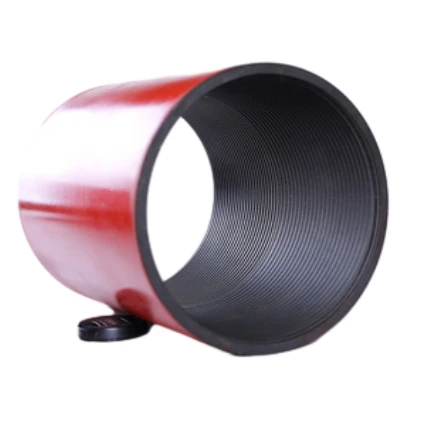

petroleum tubing coupling

Petroleum tubing coupling is an integral component in the machinery used within the oil and gas industry, playing a pivotal role in ensuring the seamless flow of oil through pipelines. As someone deeply entrenched in the sector, I've witnessed firsthand the transformative ways these small pieces of equipment contribute to the stability and efficiency of petroleum extraction and transportation processes. This article delves into the finer nuances of petroleum tubing couplings, highlighting their importance and the innovations driving their evolution in the industry.

In addition to the physical and mechanical properties, another realm of innovation lies within the digital transformation of petroleum tubing coupling processes. The integration of smart sensors and IoT technology into coupling design facilitates real-time monitoring of connection integrity and performance. These advanced features provide operators with crucial data, enabling them to preemptively address potential issues, thereby safeguarding against costly downtimes or catastrophic failures. This new realm of smart coupling is an exciting frontier, showcasing the industry's forward-thinking approach and unwavering commitment to safety and efficiency. From my extensive experience in the field, I can attest to the critical role that meticulous compliance with industry standards plays in the trustworthiness of petroleum tubing couplings. Standards such as those outlined by the American Petroleum Institute (API) and other global regulatory bodies ensure that each coupling manufactured adheres to strict quality and performance criteria. These standards are not merely guidelines but are entrenched in every stage of the coupling’s lifecycle—from conceptual design through to final production and deployment. The adherence to these protocols guarantees that the products meet the rigorous demands of oil and gas operations worldwide. Furthermore, the collaboration between coupling manufacturers and oil companies exemplifies the commitment to expertise and trust. This partnership fosters an ongoing exchange of information and innovation that refines product offerings and solves real-world challenges in the field. Manufacturers who invest in understanding the specific needs of their clients' operations and environments can offer more tailored and effective solutions. This relationship also speaks to the authoritativeness manufacturers must maintain to lead the industry in this niche. To conclude, the continuous advancement of petroleum tubing coupling technology is a testament to the significant expertise and authority held by leading manufacturers and innovators in the industry. These couplings are not mere connectors but critical components that ensure the reliability and efficiency of oil and gas operations globally. My time in the industry has shown me that the evolution of such technologies is pivotal for both current and future energy demands, reinforcing the crucial need for ongoing research, development, and collaboration. As we stand on the brink of new technological integrations, the trust we place in these rugged yet sophisticated components is well-deserved.

In addition to the physical and mechanical properties, another realm of innovation lies within the digital transformation of petroleum tubing coupling processes. The integration of smart sensors and IoT technology into coupling design facilitates real-time monitoring of connection integrity and performance. These advanced features provide operators with crucial data, enabling them to preemptively address potential issues, thereby safeguarding against costly downtimes or catastrophic failures. This new realm of smart coupling is an exciting frontier, showcasing the industry's forward-thinking approach and unwavering commitment to safety and efficiency. From my extensive experience in the field, I can attest to the critical role that meticulous compliance with industry standards plays in the trustworthiness of petroleum tubing couplings. Standards such as those outlined by the American Petroleum Institute (API) and other global regulatory bodies ensure that each coupling manufactured adheres to strict quality and performance criteria. These standards are not merely guidelines but are entrenched in every stage of the coupling’s lifecycle—from conceptual design through to final production and deployment. The adherence to these protocols guarantees that the products meet the rigorous demands of oil and gas operations worldwide. Furthermore, the collaboration between coupling manufacturers and oil companies exemplifies the commitment to expertise and trust. This partnership fosters an ongoing exchange of information and innovation that refines product offerings and solves real-world challenges in the field. Manufacturers who invest in understanding the specific needs of their clients' operations and environments can offer more tailored and effective solutions. This relationship also speaks to the authoritativeness manufacturers must maintain to lead the industry in this niche. To conclude, the continuous advancement of petroleum tubing coupling technology is a testament to the significant expertise and authority held by leading manufacturers and innovators in the industry. These couplings are not mere connectors but critical components that ensure the reliability and efficiency of oil and gas operations globally. My time in the industry has shown me that the evolution of such technologies is pivotal for both current and future energy demands, reinforcing the crucial need for ongoing research, development, and collaboration. As we stand on the brink of new technological integrations, the trust we place in these rugged yet sophisticated components is well-deserved.

Next:

Latest news

-

Tubing Crossover - API Compatible, Custom Sizes, In StockNewsNov.10,2025

-

Tubing Coupling | High-Strength, Leak-Proof Steel CouplingsNewsNov.10,2025

-

Wholesale API Threading Casing Coupling | API 5CT, Fast ShipNewsNov.10,2025

-

Pup Joint Supplier | API Certified, Custom, Quick ShipNewsNov.10,2025

-

Pup Joint Manufacturers | Precision Machined, Fast DeliveryNewsNov.10,2025

-

Tubing Coupling | Precision Steel, Leak-Proof, Fast DeliveryNewsNov.03,2025

Related Products